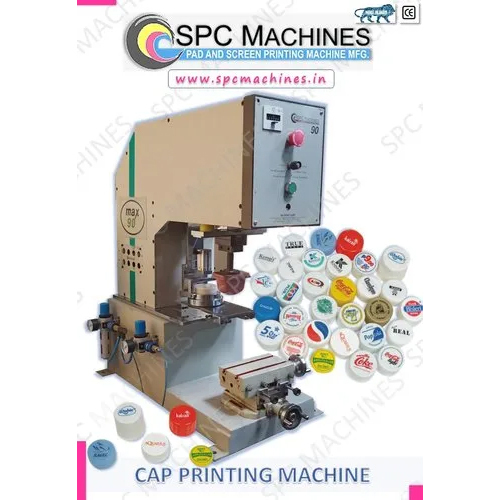

Bottle Cap Printing Machine

Product Details:

- Type Printing Machine

- Material Mild Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Plate Type Flatbed Printer

- Ink Type UV Curing Ink

- Size Standard

- Click to View more

Bottle Cap Printing Machine Price And Quantity

- 1 Number

- 195000.0 INR/Piece

Bottle Cap Printing Machine Product Specifications

- UV Curing Ink

- No

- Flatbed Printer

- Mild Steel

- Standard

- 1 Year

- Semi-Automatic

- Printing Machine

Bottle Cap Printing Machine Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 20 Number Per Month

- 6 Week

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

SPC Bottle Cap Printing Machines are designed for high-precision, high-speed, and durable printing on plastic bottle caps used in beverages, FMCG, pharmaceuticals, cosmetics, and packaged drinking water industries. These machines ensure sharp, consistent, and smudge-proof printing, making them ideal for batch codes, logos, brand names, manufacturing details, and promotional designs.

Built with advanced automation, these printing machines deliver excellent accuracy with minimal maintenance. SPC machines support various printing technologies including pad printing, UV printing, dry offset, and digital printing, depending on the production requirement. Their robust construction, user-friendly interface, and low operational cost make SPC a preferred choice among manufacturers seeking reliable cap-printing solutions.

Key Features

-

High-speed printing for large-volume production

-

Sharp & durable print quality

-

Suitable for plastic, HDPE, PP & PET caps

-

Auto-feeding and auto-collection mechanisms

-

Low ink consumption with consistent output

-

Adjustable print settings for logos, text & graphics

-

Minimal maintenance and easy operation

-

Optional UV curing system for quick drying

Frequently Asked Questions (FAQs)

1. What types of bottle caps can SPC Bottle Cap Printing Machines print on?

They can print on HDPE, PP, PET, and other plastic caps used in beverages, water bottles, cosmetics, and pharma containers.

2. What printing technologies are available?

SPC machines support pad printing, dry offset, UV printing, and digital printing, depending on the model.

3. What is the production speed?

Depending on the model, SPC machines offer high-speed printing from 5,000 to 25,000 caps per hour.

4. Can I print multi-color logos?

Yes, SPC machines support single-color and multi-color printing with precise registration.

5. Is the machine easy to operate?

Yes, SPC printing machines are designed with a user-friendly control panel, making them easy to operate even for new users.

6. Does the machine require high maintenance?

No, SPC machines are engineered for low maintenance with durable components and easy access for cleaning.

7. Do the prints smudge or fade?

No. With high-quality inks and UV curing, the prints are scratch-resistant, smudge-free, and long-lasting.

8. Is customization available?

Yes, you can customize printing plates, color setups, feeding systems, and automation levels as per production needs.

9. What industries commonly use SPC Bottle Cap Printing Machines?

Industries include:

-

Packaged Drinking Water

-

Soft Drinks & Beverages

-

Edible Oil

-

Pharmaceuticals

-

Cosmetics & Personal Care

-

FMCG Packaging

10. What is the power consumption?

Power consumption varies by model but is generally energy-efficient and suitable for continuous operations..

Product details

|

Cycles Per Hour |

1000-1200 cycles per hr and 2500-3000 caps per hr for 28-20 mm dia caps |

|

Color Printing |

yes |

|

Usage/Application |

Printing on Beverage caps, alumium caps |

|

Automation Grade |

Semi-Automatic |

|

Brand |

SPC Machines |

|

Ink Cup Diameter |

90 mm dia |

|

Plate Size |

215 mm x 100 mm |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese